Monitoring Dissolved Oxygen at Hydropower Facilities

Why Monitoring Matters

There are around 2500 hydropower facilities in the United States, generating approximately 7% of the US’s electrical energy. In addition to being a renewable power source, these dams can also function as a water supply and flood control point. As a river obstruction, hydropower dams affect water flow, spawning migrations, and water quality.

To ensure that they have a minimal impact on the environment and natural stream flow, state and federal regulations are set in place for minimum water quality standards. One such regulation is dissolved oxygen monitoring. Dissolved oxygen is the leading factor in water quality, and hydropower dams can drastically alter normal levels. Water that is diverted through a hydropower facility is typically much lower in dissolved oxygen than the rest of ecosystem. When this under-aerated water is released downstream, it decreases the oxygen content of the rest of the river, threatening aquatic life below the dam. A dissolved oxygen monitoring system ensures that the dissolved oxygen levels above and below the dam are consistently similar.

The Federal Energy Regulatory Commission (FERC) and other federal and state agencies have established reporting procedures and dissolved oxygen limits for hydropower facility operations. These monitoring and reporting procedures work to minimize dam impacts on the local aquatic habitats. The FERC also suggests mitigation measures when dissolved oxygen concentrations fall below accepted levels. Dissolved oxygen monitoring efforts allow operations managers to immediately implement these mitigation measures and minimize ecosystem degradation.

Regulatory Approaches: Overview of FERC Licensing

Nearly all non-federal hydroelectric facilities in operation are required to report to the Federal Energy Regulatory Commission (FERC). While FERC is responsible for issuing an operating license, detailed environmental regulations and requirements within that license are influenced by state and other federal agencies.

Nearly all non-federal hydroelectric facilities in operation are required to report to the Federal Energy Regulatory Commission (FERC). While FERC is responsible for issuing an operating license, detailed environmental regulations and requirements within that license are influenced by state and other federal agencies.

A state Department of Natural Resources (DNR) will often mandate a Section 401(a) Water Quality Certification under the Clean Water Act. This certification lists monitoring requirements to maintain compliance with state water quality standards. Any recommended or obligatory monitoring and mitigation efforts are generally incorporated into the FERC hydropower license.

The FERC license establishes facility-specific duties, conditions, and measures for operation. These can include minimum flow, mitigation, measurement standards (such as dissolved oxygen minimums), and narrative criteria (habitat and aquatic life). These rules will vary from state to state and even from site to site based on the dam structure and potential for environmental degradation. Both compliance with and deviation from the established license articles must be reported.

Most FERC hydropower licenses are issued for a 30-50 year term. While periods of uncontrolled non-compliance (due to weather or natural events) must still be reported and corrected, penalties are not incurred. Deliberate or systematic non-compliance, however, may be assessed a penalty.

Impoundment-type hydroelectric facilities tend to face more licensing regulations than others. The creation of a reservoir or other deep impoundment can drastically alter the local landscape and aquatic habitats. In addition to the risks of flooding, erosion, and dislocation, water quality above and below the dam can suffer. Still waters, like reservoirs, stratify easily, essentially creating two environments within the water: top and bottom. The bottom layer of water often becomes hypoxic (low dissolved oxygen levels) due to a lack of aeration and excess oxygen demand. When coupled with a deep hydro intake, the oxygen-depleted water is released downstream, lowering the dissolved oxygen content of the entire river.

To minimize this impact, FERC licenses may require dissolved oxygen monitoring upstream, downstream, and within the impoundment. The frequency of this monitoring is dependent on state-specific regulations, but continuous or near-continuous monitoring is common for deep hydro intake dams. When monitoring dissolved oxygen at hydropower facilities, real-time availability of data is crucial to instigating timely mitigation efforts. Even when sampling intervals are on a weekly basis, the ability to respond quickly will minimize the adverse effects of low dissolved oxygen and re-establish compliance with FERC.

The Essential Factor

One of the biggest impacts that hydropower plants have on the local environment is reduced dissolved oxygen levels downstream. This consequence is one of concern, as dissolved oxygen (DO) is vital to the survival of aquatic organisms. Most freshwater organisms need levels above 5 mg/L for optimum growth, and species like salmon require even higher concentrations. When DO levels decrease, fish and other aquatic life may abandon the area or die.

One of the biggest impacts that hydropower plants have on the local environment is reduced dissolved oxygen levels downstream. This consequence is one of concern, as dissolved oxygen (DO) is vital to the survival of aquatic organisms. Most freshwater organisms need levels above 5 mg/L for optimum growth, and species like salmon require even higher concentrations. When DO levels decrease, fish and other aquatic life may abandon the area or die.

While dissolved oxygen concentrations fluctuate naturally due to wind effects, underwater photosynthesis, and organism respiration, hydropower dams may cause a far more sudden and steep change. As reservoirs are usually deep enough to stratify, the drop in DO levels is often due to released water from the bottom of the reservoir (low DO), as opposed to the top (higher DO). This low dissolved oxygen content can also be caused by an overgrowth of algae that consume the oxygen in the impoundment. To minimize any environmental risk from the dam, dissolved oxygen levels should be continuously monitored for atypical changes.

Learn more in the Dissolved Oxygen section.

Dissolved Oxygen Technology

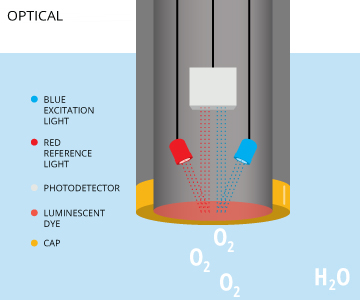

The Winkler titration method has long been heralded as the standard for dissolved oxygen (DO) measurements. However, titrations are time-consuming and difficult to conduct in the field. Instead, dissolved oxygen sensors are used as they offer real-time results and have a proven accuracy rivaling the Winkler method. DO sensors can be used in real-time monitoring systems or for spot sampling and quality assurance. There are several types of dissolved oxygen sensors on the market, including polarographic, rapid-pulsing, galvanic and optical technologies.

The Winkler titration method has long been heralded as the standard for dissolved oxygen (DO) measurements. However, titrations are time-consuming and difficult to conduct in the field. Instead, dissolved oxygen sensors are used as they offer real-time results and have a proven accuracy rivaling the Winkler method. DO sensors can be used in real-time monitoring systems or for spot sampling and quality assurance. There are several types of dissolved oxygen sensors on the market, including polarographic, rapid-pulsing, galvanic and optical technologies.

Hydropower facilitie’ dissolved oxygen monitoring systems typically use a submerged rapid-pulsing or optical sensor to measure DO. These sensors can continually monitor dissolved oxygen levels above and below the dam, providing instantaneous water quality data. Timely control measures can then be initiated based on a facility’s impacts on the ecosystem.

Learn more in the Measuring Dissolved Oxygen section.

Typical DO Monitoring System

For many hydropower facilities, it is required by FERC to monitor dissolved oxygen levels in order to prevent the destruction and dispersal of aquatic habitats. This is usually done with three monitoring stations: one upstream (for background data), one within the impoundment (for risk analysis) and one downstream (at a location affected by the dam release).

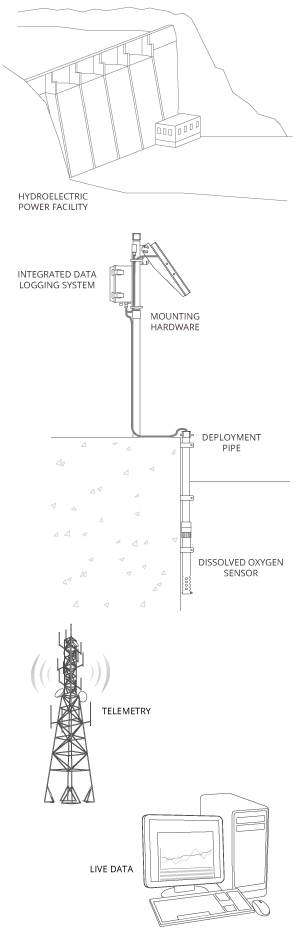

To be effective, dissolved oxygen monitoring data should be provided in real time. The easiest and most efficient way to do this is with an integrated telemetry system. A data logger can support sensors at multiple depths, while logging measurements at pre-defined intervals. With telemetry, the system can then securely transmit the data to the Internet in real time for access from any computer.

Integrated data logging and telemetry stations are customizable based on FERC license requirements. They can house as many sensors as needed, and all equipment is powered via a central battery and recharging solar panel system. With multiple telemetry options to choose from, continuous real-time data are available from any computer. This ensures that the hydropower facility’s operations continue smoothly, and any control measures can be implemented immediately if dissolved oxygen falls below a set minimum.

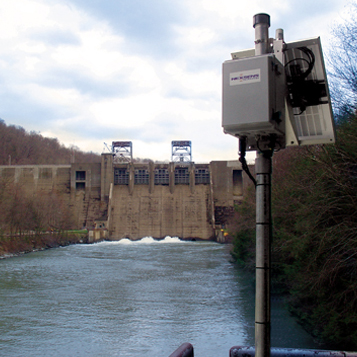

Hydroelectric Power Facility

While there are several types of hydroelectric power plants, hydropower dams are used to generate electricity through the potential energy of impounded water. The potential energy of the impoundment increases with depth, as does the potential for stratification. Water that is released from the impoundment flows through the dam, generating electricity as it spins a turbine.

While there are several types of hydroelectric power plants, hydropower dams are used to generate electricity through the potential energy of impounded water. The potential energy of the impoundment increases with depth, as does the potential for stratification. Water that is released from the impoundment flows through the dam, generating electricity as it spins a turbine.

Integrated Data Logging System

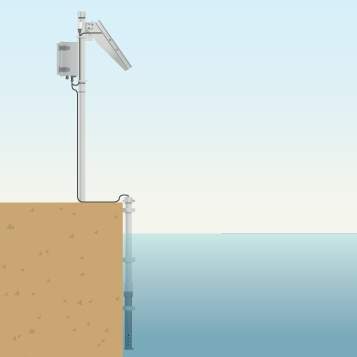

An integrated data logging system is a real-time monitoring station that houses the data logger, telemetry module, and power/charging supply. Since it is generally cost-prohibitive to run AC power to the monitoring location, integrated solar panels are used to continuously charge the 12VDC battery for autonomous operation.

Mounting Hardware

Data loggers can be mounted to a wall or pole based on location and reporting requirements. These systems can be installed on the dam or along bridges, piers, or other structures in the river or along the bank.

Deployment Pipe

PVC or metal deployment pipes are installed to protect the dissolved oxygen sensors in the water. The pipe is perforated near the sensor to allow adequate water flow for a representative measurement. In addition to shielding the sensors from debris, the pipe helps secure the equipment in a fixed position for quality data and offers easy removal for calibration.

Dissolved Oxygen Sensor

Dissolved oxygen (DO) is a primary indicator of water quality as aquatic organisms require it to survive. Rapid-pulsing and optical DO sensors can be deployed remotely to measure dissolved oxygen up and downstream from the dam. Sensors can hang at multiple depths in the water column to identify stratification issues and can monitor standalone or in a multi-parameter sonde.

Telemetry

Telemetry sends monitoring data to a central computer or web-based datacenter in real time. The wireless communication can be radio-to-shore, cellular or satellite based.

Live Data

Data can be made available 24/7 through an online datacenter. Dissolved oxygen measurements can be viewed in real time, or as a graph to see trends. Automated alerts can be sent via text or email in real time when dissolved oxygen falls below minimum standards.

Monitoring Stations

The number and location of FERC mandated monitoring stations will largely depend on license requirements and the facility’s structure. Common requirements for dissolved oxygen monitoring involve three stations. Each station should include a data logging telemetry system and as many sensors as are required. These stations can be buoy-based or mounted to a structure.

The number and location of FERC mandated monitoring stations will largely depend on license requirements and the facility’s structure. Common requirements for dissolved oxygen monitoring involve three stations. Each station should include a data logging telemetry system and as many sensors as are required. These stations can be buoy-based or mounted to a structure.

Selecting the Location

Required monitoring locations can be upstream, downstream, or within the impoundment. Upstream monitoring stations can be incorporated for background data if water quality standards are not dictated by the state. Impoundment stations can monitor multiple depths for stratification data, or simply monitor dissolved oxygen near the intake. Downstream stations can be found at the outlet, in the stilling basin or tailrace, following a weir, or further downstream of the facility.

Dissolved oxygen monitoring stations should be set at fixed locations for accurate data. Mounted systems can be placed on a structure on the shoreline or in the water, including on a pier, bridge, dam, or locks construction. Whether they are mounted to a wall or pole, the sensor should be suspended in a perforated PVC or metal pipe in the water. Structure-based telemetry systems are easy to set up wherever monitoring is needed.

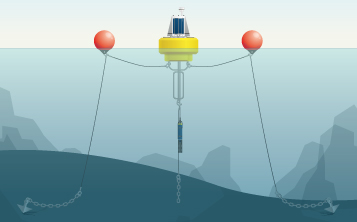

If it is necessary to collect comprehensive water-column data, a buoy-based system may be more effective. Data buoys are often used within a reservoir for a complete water quality profile. Buoy-based systems provide a stable platform that can be setup anywhere in the waterway. These systems can support multiple sensors between the surface and the bottom of the water column, providing greater insight into stratification. Like structure-based systems, data buoys house a data logger, solar-powered battery pack, and telemetry for remote communication and long deployments. While data buoys come in several sizes based on sensor load and water conditions, buoys with 150 to 450 lb. net buoyancy are generally adequate for reservoir and river monitoring.

Upstream

Upstream monitoring stations can be structure or buoy based. These systems are usually required if state water quality standards are flexible or not applicable. A monitoring system upstream of the hydropower dam provides background data on expected dissolved oxygen levels, as this water has not yet been affected by the facility. These data can then be compared to measurements made downstream of the dam to see how much effect the power plant has on water quality.

Upstream monitoring stations can be structure or buoy based. These systems are usually required if state water quality standards are flexible or not applicable. A monitoring system upstream of the hydropower dam provides background data on expected dissolved oxygen levels, as this water has not yet been affected by the facility. These data can then be compared to measurements made downstream of the dam to see how much effect the power plant has on water quality.

Reservoir/Impoundment

Lake habitats are very different from river habitats. As the flow is slower, and the water column is deeper, many characteristics of the water will change. Data buoys are typically used to monitor water quality changes in reservoirs. Deep impoundments and reservoirs are much more likely to stratify, which creates two separate aquatic ecosystems, top and bottom, often with very different dissolved oxygen concentrations. As data buoys can be centered in the deepest part of the reservoir and support multiple sensors throughout the water column, they are ideal for these monitoring conditions.

Intake

Some FERC licenses require dissolved oxygen monitoring specifically at the dam’s intake point. This is the point where water enters the facility for power generation. Intake monitoring is usually done by a mounted telemetry system, as the equipment can easily be attached to the dam structure with the sensor hanging fixed in the water. Deep hydro intakes are more likely to pull de-oxygenated water through the facility, and monitoring at the intake and outlet will provide data on how much that water will impact the river system.

Outlet/Tailrace

The hydropower outlet is the most important dissolved oxygen monitoring location. It is at this point that oxygen-depleted water is released into the river, affecting the rest of the aquatic system. Outlet-monitoring stations are typically mounted, though they can also be buoy-based. Data from an outlet dissolved oxygen monitoring station will determine how much the released water will impact the environment, and if mitigation measures should be employed.

The hydropower outlet is the most important dissolved oxygen monitoring location. It is at this point that oxygen-depleted water is released into the river, affecting the rest of the aquatic system. Outlet-monitoring stations are typically mounted, though they can also be buoy-based. Data from an outlet dissolved oxygen monitoring station will determine how much the released water will impact the environment, and if mitigation measures should be employed.

Stilling Basin

A stilling basin can be found directly below the dam. While most hydropower dam concerns revolve around too-low dissolved oxygen levels, the stilling basin can face the opposite issue, particularly if the outlet is further downstream. This basin is used to contain and slow down spillway water, which is often supersaturated with air. While the spillway water entrains oxygen for the fish below, super-saturation can cause gas bubble disease. Monitoring stations in a stilling basin often measure total dissolved gases in addition to dissolved oxygen to ensure quality DO levels while preventing supersaturated water.

Downstream

Downstream dissolved oxygen monitoring will provide data that show the actual effects of the de-oxygenated-water on the river system. As opposed to relying on flow models based on intake/outlet data, downstream monitoring reveals the actual impacts of the hydropower facility. However, as they are further away, they will not allow for as quick of a mitigation response if levels are below the accepted minimum.

Downstream dissolved oxygen monitoring will provide data that show the actual effects of the de-oxygenated-water on the river system. As opposed to relying on flow models based on intake/outlet data, downstream monitoring reveals the actual impacts of the hydropower facility. However, as they are further away, they will not allow for as quick of a mitigation response if levels are below the accepted minimum.

Pre-Deployment

To ensure accurate data, all sensors should be calibrated prior to installation and thereafter on a regular basis. If using a buoy-based system, the platforms should be fully assembled on shore prior to deployment. Regardless of the station setup and location, each complete dissolved oxygen monitoring system (sensors, data logger, telemetry, software) should be tested before deploying. While this process ensures that all equipment is functioning within specifications, it also gives everyone the chance to familiarize themselves with the system prior to deployment. Issues are always easier to deal with before installation than after.

Mounted Deployment

Mounted dissolved oxygen monitoring systems can be set up anywhere that there is a structure. Common deployment locations include pole or wall mounting on the dam, bridges, piers, docks, railroad trestles, and lock structures. The system can include a stainless steel enclosure to protect the data logger and telemetry modem from harsh weather and vandalism. The sensors hang from the station into the water within a perforated PVC or metal pipe. This pipe protects sensors from debris in the water while still permitting water flow for accurate measurements. The use of a deployment pipe also secures the sensors in a fixed position for quality data, while allowing easy removal from the water for recalibration.

Mounted dissolved oxygen monitoring systems can be set up anywhere that there is a structure. Common deployment locations include pole or wall mounting on the dam, bridges, piers, docks, railroad trestles, and lock structures. The system can include a stainless steel enclosure to protect the data logger and telemetry modem from harsh weather and vandalism. The sensors hang from the station into the water within a perforated PVC or metal pipe. This pipe protects sensors from debris in the water while still permitting water flow for accurate measurements. The use of a deployment pipe also secures the sensors in a fixed position for quality data, while allowing easy removal from the water for recalibration.

Buoy-Based Deployment

In order to maintain a fixed position in the water, a buoy-based system must be moored to the bottom. When monitoring dissolved oxygen in a reservoir, a two-point mooring is recommended. A two-point setup keeps the water column below the data buoy open for sensors to hang, without risking entanglement with the anchor lines. It also offers greater stability if there are any currents or turbulence at the station. Mooring hardware usually includes two marker buoys, stainless steel mooring lines, bottom chains, and anchors. To provide the most comprehensive water quality profile, the buoy should be deployed in the deepest part of the water way. This allows for multiple measurement depths and will best reflect the characteristics of the impoundment as a whole.

In order to maintain a fixed position in the water, a buoy-based system must be moored to the bottom. When monitoring dissolved oxygen in a reservoir, a two-point mooring is recommended. A two-point setup keeps the water column below the data buoy open for sensors to hang, without risking entanglement with the anchor lines. It also offers greater stability if there are any currents or turbulence at the station. Mooring hardware usually includes two marker buoys, stainless steel mooring lines, bottom chains, and anchors. To provide the most comprehensive water quality profile, the buoy should be deployed in the deepest part of the water way. This allows for multiple measurement depths and will best reflect the characteristics of the impoundment as a whole.

Learn more in the Buoy Mooring section.

Data Management

A major part of FERC reporting is collecting and accessing the monitoring data. While it is possible to manually measure and record data onsite, the use of a data logger and telemetry system is more cost effective. The ability to save, send and view measurement data in real time is efficient and convenient, particularly when frequent monitoring intervals are required to maintain compliance. Real-time data and alerts also allow for a faster response time when adverse conditions occur.

A major part of FERC reporting is collecting and accessing the monitoring data. While it is possible to manually measure and record data onsite, the use of a data logger and telemetry system is more cost effective. The ability to save, send and view measurement data in real time is efficient and convenient, particularly when frequent monitoring intervals are required to maintain compliance. Real-time data and alerts also allow for a faster response time when adverse conditions occur.

Learn more in the Monitoring Equipment section.

Quality Assurance

Accurate data will help a hydropower facility remain in compliance with FERC license regulations. In order to maintain the highest levels of accuracy, best practice recommends cleaning and calibrating the sensors at regular intervals. Cross-checking sensor data with a separate instrument is also recommended. This cross-check verifies that the data are accurate and within sensor specifications. It will also confirm whether or not the power plant is compliant with the license.

System Maintenance

While a FERC license may not explicitly require maintenance intervals for monitoring equipment, periodic upkeep and calibration is necessary in order to prevent sensor drift and ensure a longer instrument life. Sensor maintenance includes cleaning (especially if an instrument is not self-wiping) and replacing any deteriorating or missing O-rings to prevent water ingress. If a monitoring station is measuring additional parameters beyond dissolved oxygen (such as temperature or total dissolved gases), further field servicing may be required. Maintenance intervals are largely dependent on the sensor technology used, site conditions and variables such as the potential for bio-fouling. Dissolved oxygen sensors should be checked and calibrated every 2-4 weeks or as recommended by the manufacturer.

Dissolved oxygen sensors only require a single-point calibration, though a two-point calibration can be used to verify accuracy across the entire measurement range. A single-point calibration is typically done at 100% air saturation, while a two-point calibration includes a zero oxygen solution. The 100% air saturation calibration solution can be achieved with air-saturated water or water-saturated air. For long-term studies, it is recommend to calibrate with air-saturated water, though water-saturated air calibrations are easier to conduct in the field. If a two-point calibration is performed, the zero oxygen solution can be made or purchased.

When monitoring dissolved oxygen at a hydropower dam, it is useful to have a spare sensor or sonde available. Keeping a spare dissolved oxygen sensor on hand will reduce downtime due to unforeseen sensor failure, which could affect FERC reporting. If needed, the spare DO sensor can easily be field swapped during calibration or routine maintenance checks.

For greater details regarding maintenance requirements and sensor calibration, the manufacturer’s user manual should be referenced.

Performance Verification

In addition to keeping the monitoring equipment calibrated, it’s important to periodically verify that the dissolved oxygen sensors are providing accurate data. The best way to achieve this is by checking dissolved oxygen at the monitoring station using a separate, portable instrument. This is also known as spot sampling.

In addition to keeping the monitoring equipment calibrated, it’s important to periodically verify that the dissolved oxygen sensors are providing accurate data. The best way to achieve this is by checking dissolved oxygen at the monitoring station using a separate, portable instrument. This is also known as spot sampling.

There are several portable dissolved oxygen measurement methods that can be used for spot sampling. The first method uses a sensor attached to a handheld display, also known as a dissolved oxygen meter. The sensor can be connected directly to the display or through a multi-parameter sonde. The spot sampling equipment can be lowered into the water column to a depth that matches the stationary sensors. While it is at that depth, a dissolved oxygen measurement can be taken and immediately displayed on the meter. The portable system data can then be compared to the stationary monitoring system and checked for discrepancies.

When used for spot sampling, a dissolved oxygen sensor can be optical, galvanic or polarographic. Optical DO sensors are recommended for their accuracy and comparability to deployed instruments (as most deployed DO sensors are optical). Galvanic and polarographic sensors are more economical and can take quicker readings than optical sensors, but they are flow dependent. This means that the sensors must be stirred if the waterway has low or no flow. Spot sampling sondes are recommended if the deployed instrument is also a sonde, so that all measured parameters can be checked using similar instrumentation.

The second portable verification method uses titration. The Winkler titration method requires taking a water sample, and then fixing and titrating it to determine the dissolved oxygen concentration. This can be done with a field kit or in the lab. However, as this method uses a sample instead of an in-situ measurement, it is more time-consuming to conduct and a water sample will need to be taken at each measurement depth.

Recommended Equipment

While there are a variety of dissolved oxygen monitoring instruments to choose from, some stand out above the rest. Fondriest Environmental has selected these products as the best in their field for their accuracy, dependability and value. Together, they provide an innovative and responsive real-time dissolved oxygen monitoring system. The YSI ODO RTU optical dissolved oxygen sensor combines advanced luminescent technology with the reliability of a smart sensor – including calibration storage and a digital output. The NexSens X2 data logging system arrives fully assembled, tested and operational with integrated solar power and a choice of real-time radio, cellular, and satellite communications. Alone, real-time data are good, but with remote data collection, 24/7 access from any computer, instant alarm notifications and trend tracking, the intuitive WQData LIVE takes real-time data to the next level.

Learn more about these products

- YSI ODO RTU Optical Dissolved Oxygen Sensor

- NexSens X2 Environmental Data Logger

- NexSens WQData LIVE Web Datacenter

Cite This Work

Fondriest Environmental, Inc. “Monitoring Dissolved Oxygen at Hydropower Facilities.” Fundamentals of Environmental Measurements. 27 Oct. 2014. Web. < https://www.fondriest.com/environmental-measurements/environmental-monitoring-applications/monitoring-dissolved-oxygen-hydropower-facilities/ >.