It’s a Buoy! Highlighting the New NexSens XB-200 Data Buoy

The NexSens XB-200 data buoy deployed on the Fondriest Field Station lake. (Credit: Emma Jones / Fondriest Environmental)

The NexSens XB-200 data buoy deployed on the Fondriest Field Station lake. (Credit: Emma Jones / Fondriest Environmental)As scientists seek to better understand aquatic ecosystems, utilizing small data buoys to monitor offshore and cover more water is becoming commonplace. The new NexSens Technology XB-200 data buoy was designed for inland and coastal monitoring applications.

Although compact, the platform is designed with adequate space for multiple sensors and measurement electronics. When configured with the NexSens X3 data logger with IoT connectivity, internal batteries, solar panels, select sensors, and other accessories, the new buoy provides an off-the-shelf solution for any monitoring project.

The new buoy concept was developed by the NexSens product development team with significant user input. After reviewing the needs of current clients and future applications, it was clear that the XB-200 would need to meet four primary functions.

First, the new buoy needed to be small, lightweight and easy to deploy from a small boat. Second, the buoy needed to be foam-filled with an impact-resistant surface, which can endure years of service in the harshest conditions and roughest of seas.

Third, solar panels needed an unbreakable polymer substrate rather than glass and must be easily replaced in the field. Lastly, the new buoy electronics needed to be conveniently located for quick access, troubleshooting and replacement.

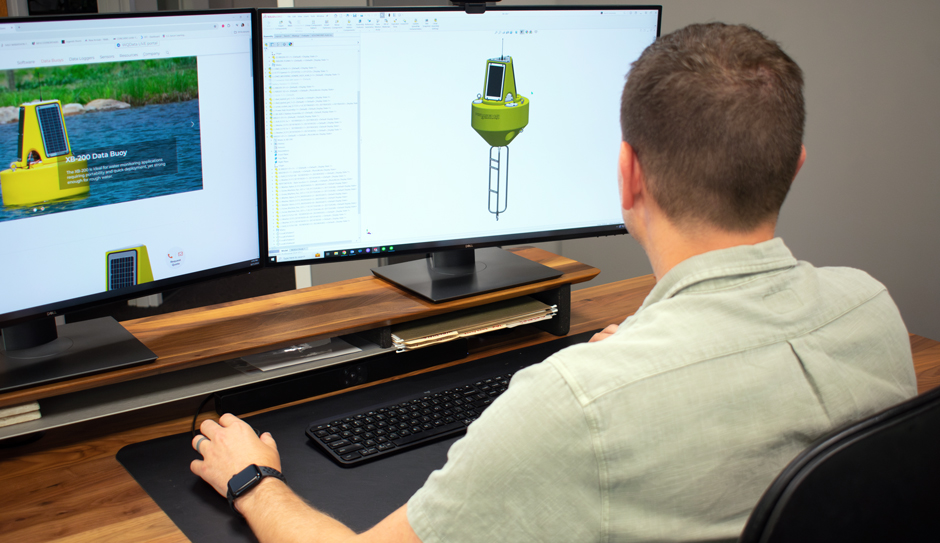

Designing the XB-200

Keeping in mind the primary goals of the new buoy, the product development team began sketching and developing concepts, weighing options, and bouncing ideas back and forth. Throughout development, each idea, sketch, and prototype of the buoy was compared to the list of client needs.

Ease of use, serviceability, construction materials, overall weight, dimensions, and possible methods of manufacturing were all factors the NexSens team carried with them throughout each stage of the process.

Concept illustrations of the NexSens XB-200 Data Buoy (Credit: Emma Jones / Fondriest Environmental)

The team also paid special attention to the net buoyancy so that the buoy could carry a significant payload, available freeboard to ensure electronics and solar panels were mounted above the waterline, stability so that the buoy avoided excessive listing, and hydrodynamics for dissipating wave energy.

Mechanical engineers began developing a solid model using 3-dimensional CAD software with the features, draft angles, and surfaces required for molding. A UV-stabilized polyethylene plastic was chosen as it has superior impact resistance and color fastness.

NexSens engineers designing the XB-200. (Credit: Emma Jones / Fondriest Environmental)

Early designs also included three 4-inch sensor deployment ports to provide quick access to subsurface instrumentation. Adequate mounting space and locations were allocated for battery power and solar charging options to support frequent sampling and transmissions.

One of the most important factors to consider was the durability of the platform. While other data buoys can be pierced or crushed by collisions, vandalism, or other damages, the XB-200 needed to be foam-filled, allowing it to stay afloat even if the hull is compromised.

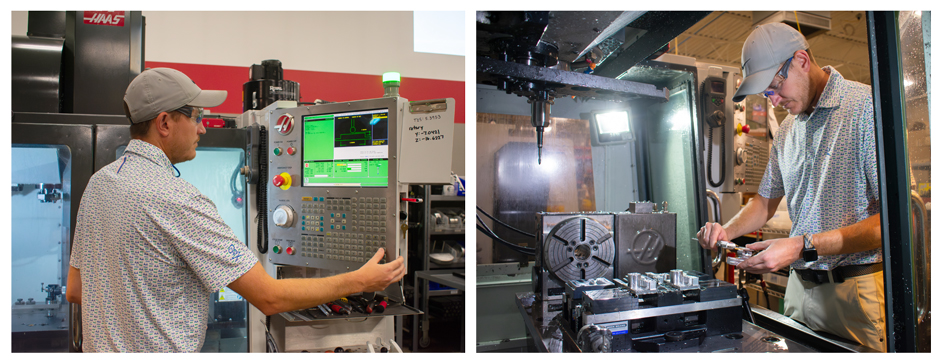

With the platform designed, the NexSens team began fabricating accessories and components. Battery support, connectors and signal splitters, sealed lids and plates were manufactured using computer numerical control (CNC) machinery. The engineers used computer aided manufacturing (CAM) models to work out tooling, establish machining procedures, and then selected materials that would hold up well in harsh marine environments.

(Left) NexSens engineer configuring the CNC mill; (Right) NexSens engineer inspects CNC machine part. (Credit: Emma Jones)

Different from the existing NexSens buoy line, the XB-200 requires rotational molding to set the plastic in the distinct new shape. While most industry molders are used to high-volume production of very low-tolerance parts, the XB-200 demanded stricter construction.

After visiting several rotational molding companies, NexSens selected Hedstrom Plastics as the partner. With months of back-and-forth interaction with Hedstrom and the mold builder, the team finally had their first prototypes.

Photos of the rotational molding process. (Credit: Jerred Copen / Hedstrom Plastics)

Testing the XB-200

Early prototypes were cut in cross sections to examine the wall thickness and foam capacity. Weights and densities of both the plastic and foam were confirmed. Color fastness, galvanic corrosion, impact resistance, threaded insert pull-out strength and mooring connections were tested.

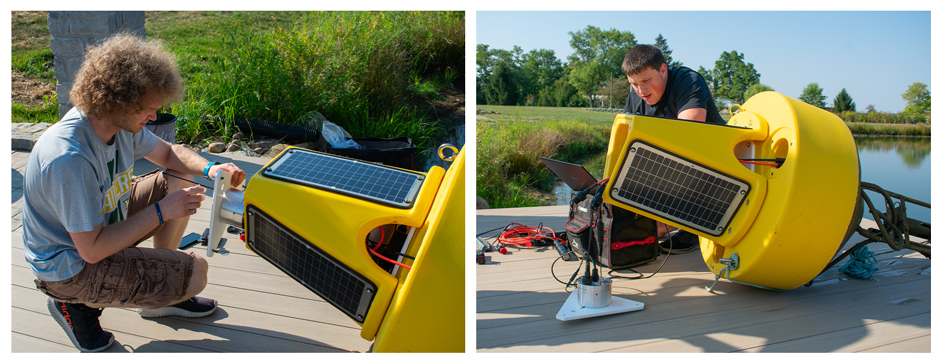

In addition to the lab testing, the XB-200 was field-tested at the Fondriest Center for Environmental Studies. Deployed in tandem with a CB-150 data buoy, the XB-200 was placed in the field station lake to compare the performance of the XB-200 against a tried-and-true platform.

A field deployment allowed the Science Team to test the field durability of the buoy and the ease of deployment and integration. Joe Davidson, an Applications Scientist with NexSens Technology, integrated both buoys.

While the CB-150 buoy was equipped with the legacy X2 data logger, the XB-200 represented NexSens’ new generation of monitoring equipment with the new X3 data logger. Both equipped with a YSI EXO3 sonde, the team tested the stability, consistency, and quality of the XB-200 compared to the CB-150.

NexSens employees deploying the XB-200 at the field station. (Credit: Emma Jones / Fondriest Environmental)

“The XB-200 is significantly lighter than previous NexSens buoys of similar size, offering the same buoyancy with improved maneuverability,” states Davidson.

He continues, “Deployment required only two people and minimal equipment. The buoy features the same mounting options as other NexSens buoys, including an instrument cage, pass-through ports, and top eye nuts for attaching sensors and the temperature string.”

The testing also demonstrated that the XB200 buoy provides a higher freeboard and a considerable improvement in stability.

Since its initial deployment with only an EXO sonde and data logger, the XB-200 has remained deployed at the field station, now additionally equipped with an ANB Calibration Free pH Sensor, Seametrics Turbo Turbidity Sensor and NexSens temperature string.

In addition to the field station deployment in Ohio, several beta units were deployed in Texas. Following this deployment, the client has since become the largest XB-200 customer and continues to project many more buoy systems in the coming months.

Satisfied with the lab and field performance of the XB-200 and X3, NexSens released both products in the Summer of 2024.

A New Wave of Buoy Technology

As it stands today, the XB-200 fulfils all of the client needs the team set out to solve. The buoy is lightweight, allowing for quick deployment, all while being strong enough for rough water. Impact-resistant and with 200 lb. of buoyancy, the XB-200 offers a durable platform for a variety of monitoring applications.

NexSens employees installed and connected an X3 data logger to the XB-200 and attached sensors at the field station. (Credit: Emma Jones / Fondriest Environmental)

0 comments