Redefining Remediation: ecoSPEARS’ Green Solution for a Cleaner Future

Co-founder and CEO of ecoSPEARS Sergie Albino is dedicated to restoring the health and vitality of the environment for all people. (Credit: ecoSPEARS)

Co-founder and CEO of ecoSPEARS Sergie Albino is dedicated to restoring the health and vitality of the environment for all people. (Credit: ecoSPEARS)An environmental remediation strategy that has the potential to remove PCBs, dioxins, PAHs, DDT and other persistent toxins permanently may sound too good to be true, but recent innovations introduce a solution that removes these chemicals from the environment forever. This potential to change the industry forever is what attracted ecoSPEARS CEO, Serg Albino, to the industry in 2015.

ecoSPEARS offers a green decontamination strategy that is built off of the need to create a cleaner world for the future. Persistent toxins have saturated the environment, contaminating soils, sediment and water sources, all of which impact human and ecosystem health. Toxins enter the food chain through smaller organisms that are exposed and then eaten by larger species who continue to carry the toxins throughout the ecological chain.

Green Solutions Inspired by NASA Sustainability

With a background in aerospace engineering at NASA and the Department of Defense, Albino found himself interested in how he could change the remediation sector and make it greener. “NASA is always in this sustainability model because every time we send stuff to space, what you send up there is what you’re going to expose the astronauts to. They’re going to breathe it in because it’s a closed volume—it’s not like you can open the window.”

This sustainability model is what led to the first draft of the ecoSPEARS technology in 2012. Albino tells an elaborate tale of Dr. Jackie Quinn making the discovery as a result of a grant and request from the Navy to develop a solution that removes PCBs from waterways after it’s entered the sediment. With the proposal in hand, the team of NASA scientists, Dr. Jackie Quinn, Dr. Bobby Devore and Dr. Jill Maloney, set out to find a solution.

The ecoSPEARS team executed a year-long effort of cleaning up industrial chemical contamination, also known as “forever chemicals,” from the Anacostia River near Washington D.C. (Credit: ecoSPEARS)

Persistent toxins all share the similar characteristics of being hydrophobic as well as inorganic. “She basically said, ‘Okay, like versus like, they attract—organic or non-organic.’ So the legend goes that Dr. Quinn ran down to the Sonny’s BBQ restaurant in the Operations & Checkout, or O&C, building at NASA and grabbed a bunch of straws,” begins Albino.

She took the straws back to her desk, where she used a hair-crimping iron to seal the straws, one of which was filled with green solvent. Albino continues, “And lo and behold, those were the first Sorbent Polymer Extraction And Remediation System (SPEARS). The plastic with green solvent allowed more absorption of chemical contamination because the green solvent expanded the plastic lattice and allowed for the contaminants to go into the green solvent, allowing the plastic to absorb more contamination.”

The success of the technology inspired Albino to start ecoSPEARS with Dr. Quinn’s technology as the leading solution for sediment remediation. The success of the SPEARS technology uniquely positioned the company in other avenues of environmental remediation, specifically in soils with their ecoĀINA as well as wastewater treatment with the ecoCUBE.

Cradle-to-Cradle Innovation

The principle behind each of these solutions is to create something long-lasting that solves the problem forever, not just temporarily. Traditional soil remediation involves the removal of contaminated dirt, which is then shipped to a designated incineration site for burning. The removal site must then be restored by finding non-contaminated soil and filling in the empty space. Sediment treatment involves a similar process—historically involving the removal of contaminated sediments followed by a sediment capping procedure.

One of the main environmental concerns with these current solutions is how the transport of these contaminants impacts the environment. In particular, current solutions are largely inaccessible for islands like Hawaii and Guam, as well as other areas that do not have easy access to burn facilities. “It’s not very cost effective, and it’s not very sustainable either. You’re essentially trading off clean water and clean soil for clean air at that point,” states Albino.

Instead of removing the sediment to be shipped elsewhere, ecoĀINA is an ex-situ soil washing remediation that involves removing the contaminated sediment and then washing it in a chamber nearby to separate contaminants from the soil. Once cleaned, the soil can be put back, meaning there is no transport to or from required.

Invented, patented, and validated by NASA scientists and engineers, ecoSPEARS’ technologies exemplify scientific excellence and innovative solutions. (Credit: ecoSPEARS)

The goal is to clean the soil enough to meet residential levels wherein the previously contaminated soil can be restored, saving the need to find clean fill soil. When residential levels cannot be achieved due to high levels of contamination, boundary caps can be installed to protect the public from being exposed. Albino expands, “We’re probably batting close to 95% average of getting everything down below one part per million on soil remediation.”

In terms of sediment, ecoSPEARS are different from ecoĀINA in that it is an in-situ solution–intended to remain in the environment until the source of the contaminant is resolved. “As long as we have our SPEARS in the ground, we know that it’s always going to be absorbed into the SPEARS and trapped in the SPEARS instead of going into the fish,” explains Albino. “We want that to actually be looked upon more as—not a Tylenol fix, but more of a holistic process of environmental remediation [. . .] But like Kobe always says, ‘Job’s never done.’”

The SPEARS are deployed in dynamic environments as a part of a long-term reconstructive program. The SPEARS can hold a large volume of contaminants, so they only need to be removed in the case of testing or when the project has been completed. The idea behind both solutions is that they are built to clean the environment without creating new problems for the next generation.

Albino and the rest of the ecoSPEARS team hold sustainable remediation as the most important factor to consider in development. “This is what I tell people that want to learn more about the environmental sector, ‘There is no happy ending.’ The contamination that we think, or things that we think are bettering our lives today, because they’re making our lives convenient—we find out later on that it’s harmful.”

Albino expands, “I think as a society, we just need to be mindful and start always thinking—instead of thinking about this cradle to grave mentality, we need to start thinking about cradle to cradle. What are we using today that our kids and our grandkids can utilize later? So they don’t have to deal with the health issues that we’ve caused to their generation for our convenience today.”

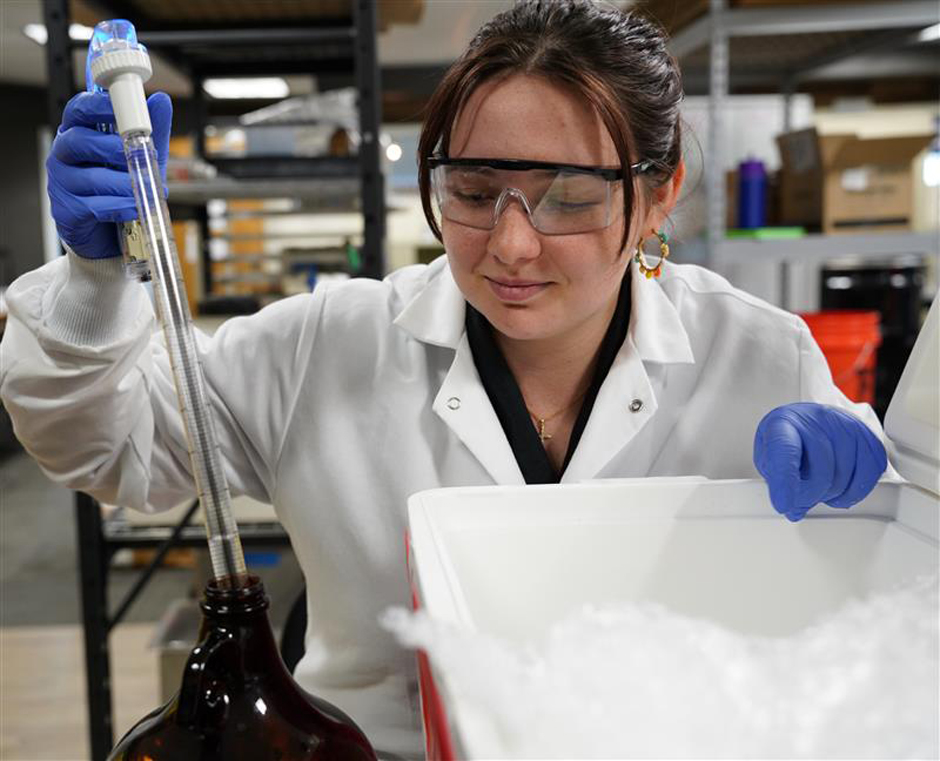

ecoSPEARS utilizes its clean tech solutions to provide onsite environmental monitoring of chemical contamination post-remediation.

(Credit: ecoSPEARS)

Instrument of Change, Hope for the Future

Moving forward, ecoSPEARS is dedicated to innovation and sustainability. While Albino is an aerospace engineer by trade and his co-founder and executive vice president, Ian Doromal, is a marketing and business-oriented individual, he believes that this makes ecoSPEARS different from other solutions.

Albino explains, “Just like in anything you do, when you become a subject matter expert, you become pigeon-holed to only what you know, and what you see. So we’re the guys that are like two-year-old kids that you typically will yell at, because they’re always asking why! Why is the sky blue? Why are you digging up that dirt? Why are you sending it to California? Why are you burning dirt? Isn’t it hard to burn dirt?”

Asking these questions led to the birth of ecoSPEARS’ solutions and will continue to drive the company and industry’s future. Moving forward, the company is interested in integrating the SPEARS with AI to better inform clients and regulators on how the waterway is improving. The eventual goal is to build sensor technology into each spike or each mat to report conditions in real-time rather than manually removing a spike each time.

Also on the list for future improvements is the development of a portal wherein the data can be available at different levels to the public, researchers and regulators. This portal would be powered by sensor technology and data buoys that can monitor other conditions in the waterways, all of which would build a more comprehensive picture of the environment’s health.

Ultimately, Albino believes that asking questions and pushing for things to change is what has to happen to change the future and achieve the larger goal of a cleaner planet. “We bring innovation. The biggest enemy to the sector is the lack of innovation—it’s not the people, and it’s not the contamination—the contamination is what helps our lives to be more convenient. But it’s a lack of innovation, to clean it up after we let it out to the environment.”

Being able to help people and clean up the world is what drives ecoSPEARS to continue innovating and growing. Albino explains that the company’s future is to continue to partner with other sectors dedicated to the same cause. As a team, ecoSPEARS is committed to doing things bigger than themselves and working to extend help and partner with groups across the globe. After all, “It’s a big world to clean up, and we want to work with like-minded folks,” states Albino.

ecoSPEARS’ in-situ sediment remediation technology, once deployed in rivers, waterways, and wetlands, serves as cleantech Active Monitoring Samplers (AMS) to monitor PCB, PFAS and other Persistent Organic Pollutant (POPs) samplers. (Credit: ecoSPEARS)

0 comments